Spiral Wound Pipe Lining

6″ – 200″+ Pipe Lining

Live Flow Installations

100% Trenchless

Spiral Wound Pipe Lining

6" - 200"+

Live Flow Installations

100% Trenchless

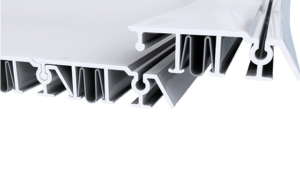

Fully Structural PVC Liners

Spiral Wound is a trenchless pipe lining method for sewers, storm drains and culverts. Our pipe liners provide fully structural rehabilitation using mechanically wound PVC.

The Spiral Wound process is 100% mechanical and can be installed in live flow. Pipe liners are constructed directly onsite using only existing access points, such as a standard manhole. This method meets design standards such as ASTM 1741-18 and ASTM 1697-18; specifying the proper installation of mechanically and machine wound PVC profiles.

What is Trenchless Pipe Lining?

Trenchless pipe lining, also known as trenchless pipeline rehabilitation, is an innovative method of restoring aged and deteriorated pipelines without excavation. Without the need to dig, trenchless pipeline rehabilitation is more affordable and eco-friendly. The technology used by SEKISUI SPR allows us to access and repair a variety of pipe diameters and shapes.

6" - 200" Fully Structural Pipe Lining

Spiral Wound is a trenchless pipe lining method for sewers, storm drains and culverts. Our pipe liners provide fully structural rehabilitation using mechanically wound PVC.

The Spiral Wound process is 100% mechanical and can be installed in live flow. Pipe liners are constructed directly onsite using only existing access points, such as a standard manhole. This method meets design standards such as ASTM 1741-18 and ASTM 1697-18; specifying the proper installation of mechanically and machine wound PVC profiles.

There are 3 methods of installation for Spiral Wound pipe rehabilitation. Each method serves a range of pipe diameters spanning from 6″ to over 200″.

Videos, Projects & Articles

Spiral Wound Lining Process

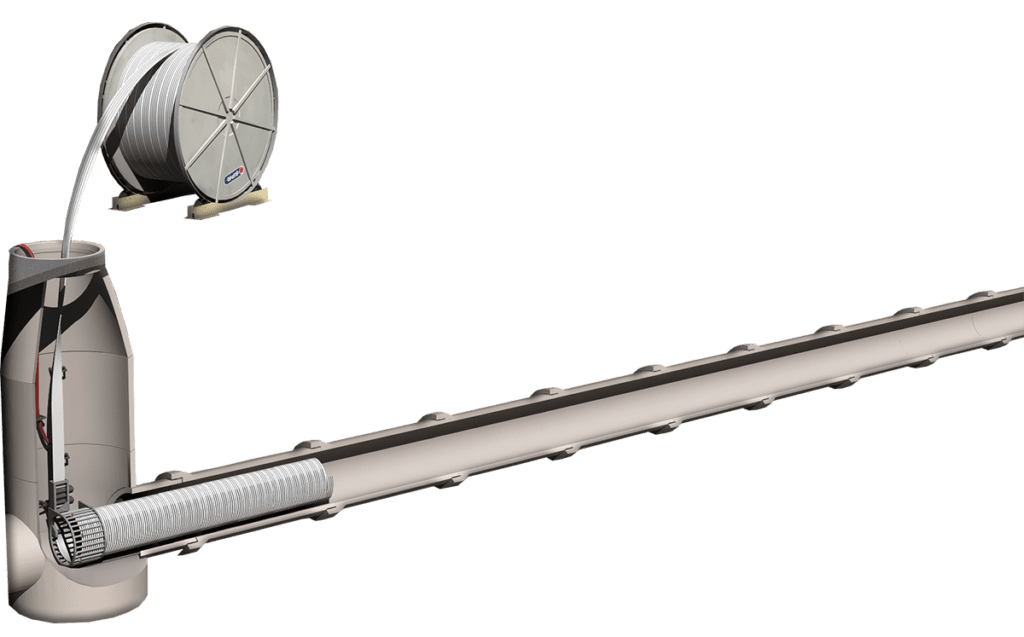

A spool above ground feeds the PVC profile strip through existing access points. No further site excavation is necessary.

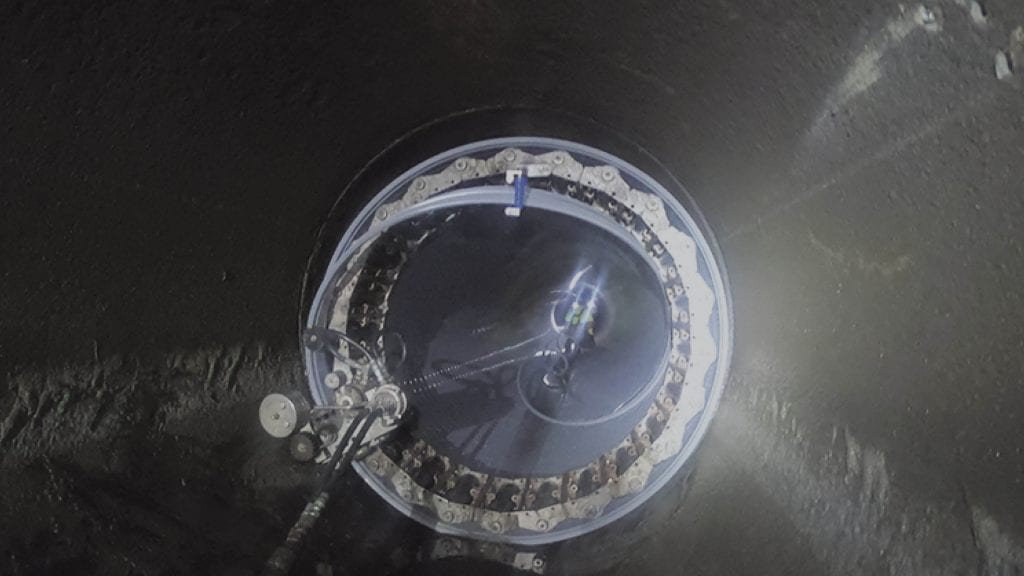

The winding machine forms the liner directly inside the sewer, storm drain or culvert. Liner is either pushed (as seen in image) down the pipeline or pulled using a traversing machine. The method used depends upon host pipe diameter.

The profile edges are locked during winding, creating a water-tight seal. The pipe liner is either installed as a tight-fit (SPR™EX & SPR™TF) or requires annular space grouting (SPR™) to finish the installation process.

Little/No Bypass

Our trenchless pipe liners are successfully installed in live flow conditions, which saves on construction costs.

Spiral Wound Liners can operate typically with around 25%-30% flow in pipe.

The Spiral Wound Lining Process

A spool above ground feeds a continuous strip of PVC strip through existing access points, such as a manhole.

The winding machine then forms the liner directly inside the sewer, storm drain or culvert. The pipe liner is either installed as a tight fight (SPR™EX & SPR™TF) or requires annular space grouting (SPR™) to finish the installation process.

Little or No Bypass

Our trenchless pipe liners are successfully installed in live flow conditions, which saves on construction costs.

Spiral Wound Liners can operate typically with around 25%-30% flow in pipe.

Trenchless Lining Methods

3 Spiral Wound installation methods based upon pipe diameter

SPR™EX is a tight-fit liner suitable for small-diameter sewers, storm drains, and culverts. It does not require annular space grouting.

The PVC profile is wound directly into the host pipe by the hydraulic winding machine in the access chamber.

SPR™TF/RO is a trenchless pipeline rehabilitation method for mid-range diameter sewers, storm drains, and culverts that does not require annular space grouting.

This method uses two different winding machines that traverse the pipeline while constructing a tight-fit liner.

SPR™ is used to repair large round and non-round sewers, storm drains, and culverts.

The PVC profile is wound into the pipe by a traverse winding machine, and then grout fills the annular space.

Need Information?