Spiral Wound Pipe Lining

150 mm – 5500+ mm Pipe Lining

Live Flow Installations

100% Trenchless

Rehabilitation Technology

Deposits, leaking joint cracks, aging and corrosion pose a threat to pipelines. The conservative approach to pipeline repair by means of excavation is expensive, time‐consuming, and noisy and can result in major traffic disruptions.

SEKISUI´s patented, certified, award‐winning trenchless technologies are perfect for rehabilitation of gravity pipelines − providing solutions that are high quality, cost‐effective and environmentally friendly. The spiral‐wound lining technologies are being used successfully all over the world for the rehabilitation of challenging circular and custom shapes and proves its reliability even under extreme conditions.

Spiral Wound Pipe Lining

150 mm - 5500+ mm

Live Flow Installations

100% Trenchless

Spiral Wound Lining

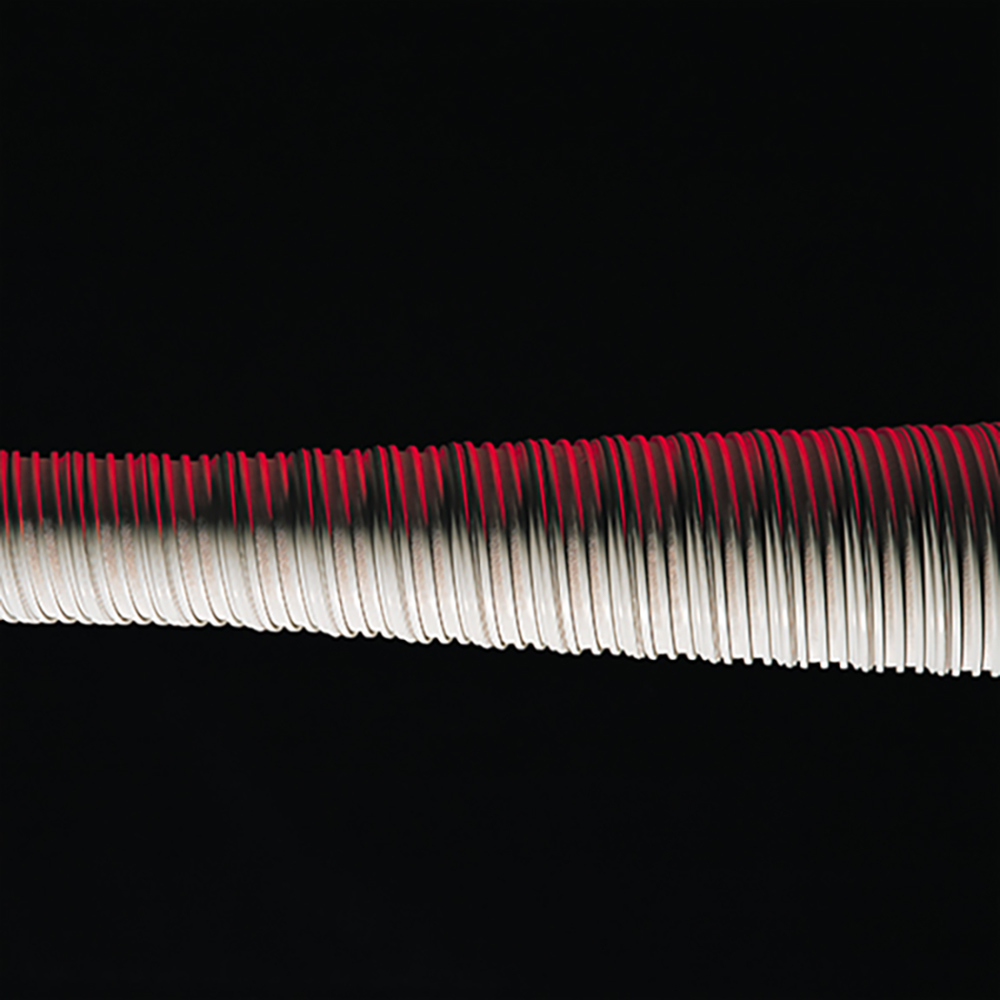

The spiral‐wound lining technologies are suitable for the rehabilitation of gravity pipelines. These trenchless technologies based on the principle of spiral winding an extruded plastic profile from PVC or HDPE into a liner. The profiles with high ring stiffness and low weight can be steel‐reinforced, if needed. Directly in the host pipe the single profile strips will be joined together by using a special winding machine and will form a liner.

Depending on the system, the host pipe will be rehabilitated with a close fit liner or a liner with an annulus, which is filled with a high performance grout. The result is a loadbearing, homogeneous and watertight pipe system. The spiral wound lining method is applicable for large diameter and/ or unique shaped pipelines. Installation can be carried out without excavation and without interrupting the flow in the line, so that in most cases, there is no need for bypass pumping.

The spiral‐wound lining technologies are suitable for a wide range of diameters and shapes. Installation can be carried out without excavation and without interrupting the flow in the line, so that in most cases, there is no need for bypass pumping.

The Spiral Wound Lining Process

The spiral‐wound lining technologies are suitable for the rehabilitation of gravity pipelines. These trenchless technologies based on the principle of spiral winding an extruded plastic profile from PVC or HDPE into a liner. The profiles with high ring stiffness and low weight can be steel‐reinforced, if needed. Directly in the host pipe the single profile strips will be joined together by using a special winding machine and will form a liner.

Depending on the system, the host pipe will be rehabilitated with a close fit liner or a liner with an annulus, which is filled with a high performance grout. The result is a loadbearing, homogeneous and watertight pipe system. The spiral wound lining method is applicable for large diameter and/ or unique shaped pipelines. Installation can be carried out without excavation and without interrupting the flow in the line, so that in most cases, there is no need for bypass pumping.

The spiral‐wound lining technologies are suitable for a wide range of diameters and shapes. Installation can be carried out without excavation and without interrupting the flow in the line, so that in most cases, there is no need for bypass pumping.

Trenchless Lining Methods

Spiral Wound installation methods based upon your application.